How a Qatar based mechanical, electrical & plumbing (MEP) contracting company fixed inventory gaps with Axiever

Key facts at a glance

- Executing 8–12 parallel MEP projects at any given time

- Managing 3,500+ SKUs across warehouses, yard, and sites

- High-volume materials include cables, ducts, pipes, valves, fittings, panels, and HVAC components

- Inventory value spread across projects, warehouses, and open yard stock

- Tight project timelines aligned with Qatar construction compliance and handover schedules

Business background

The company is a Qatar based MEP contracting firm executing multiple HVAC, electrical, plumbing and fire system projects simultaneously.

Inventory relied on manual tracking, spreadsheets and informal coordination between procurement, stores and site teams. As project volume increased, this lack of structured control began to impact project timelines, cost accuracy and operational confidence.

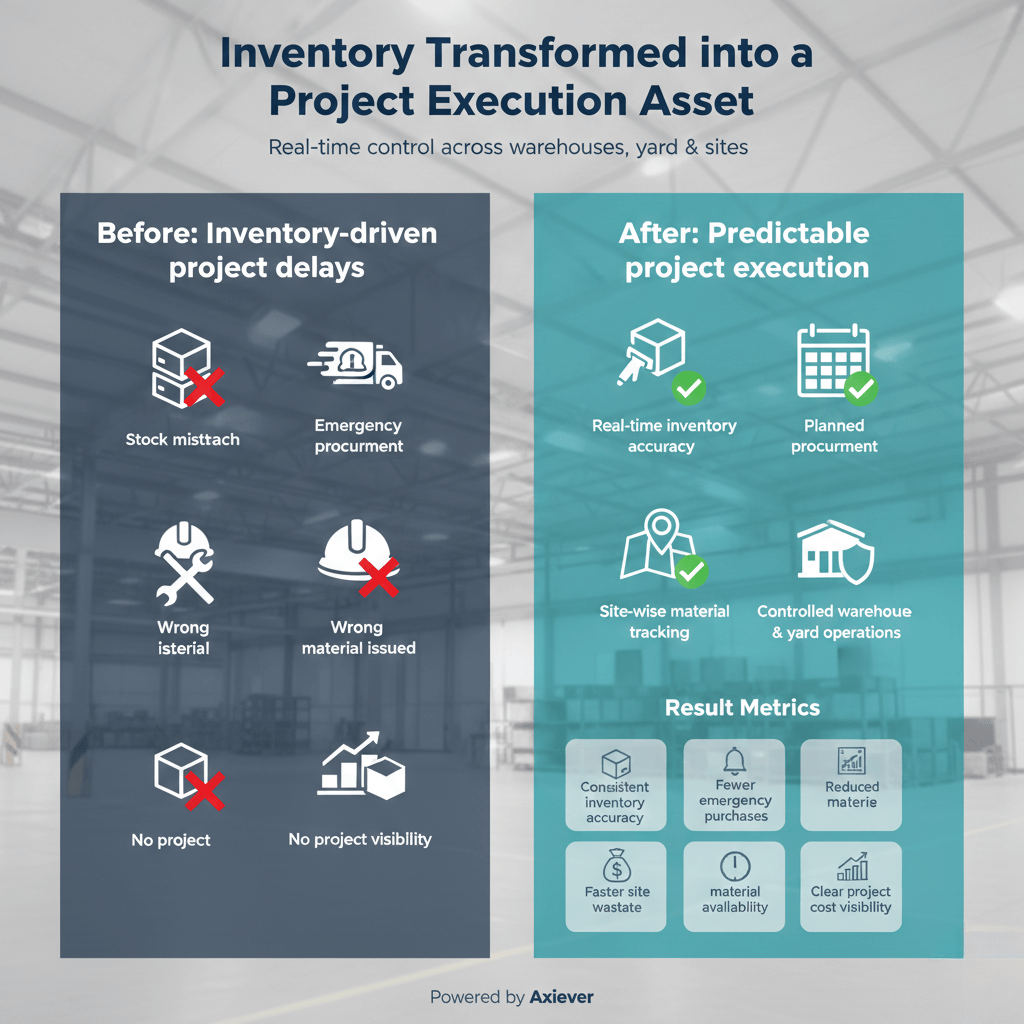

The challenge: inventory gaps slowing project execution

- System stock did not match physical stock

- Duplicate item codes for the same materials

- No low-stock or fast-moving alerts

- Overstock and dead stock not visible

- Project-critical materials going out of stock

- Manual GRN quantity mismatches

- No batch, lot or expiry tracking

- Incorrect picking and site issues

- Damaged and expired stock mixed with usable material

- No consolidated view across warehouse, yard and sites

- Yard materials issued without system entry

- No visibility of inventory value vs project usage

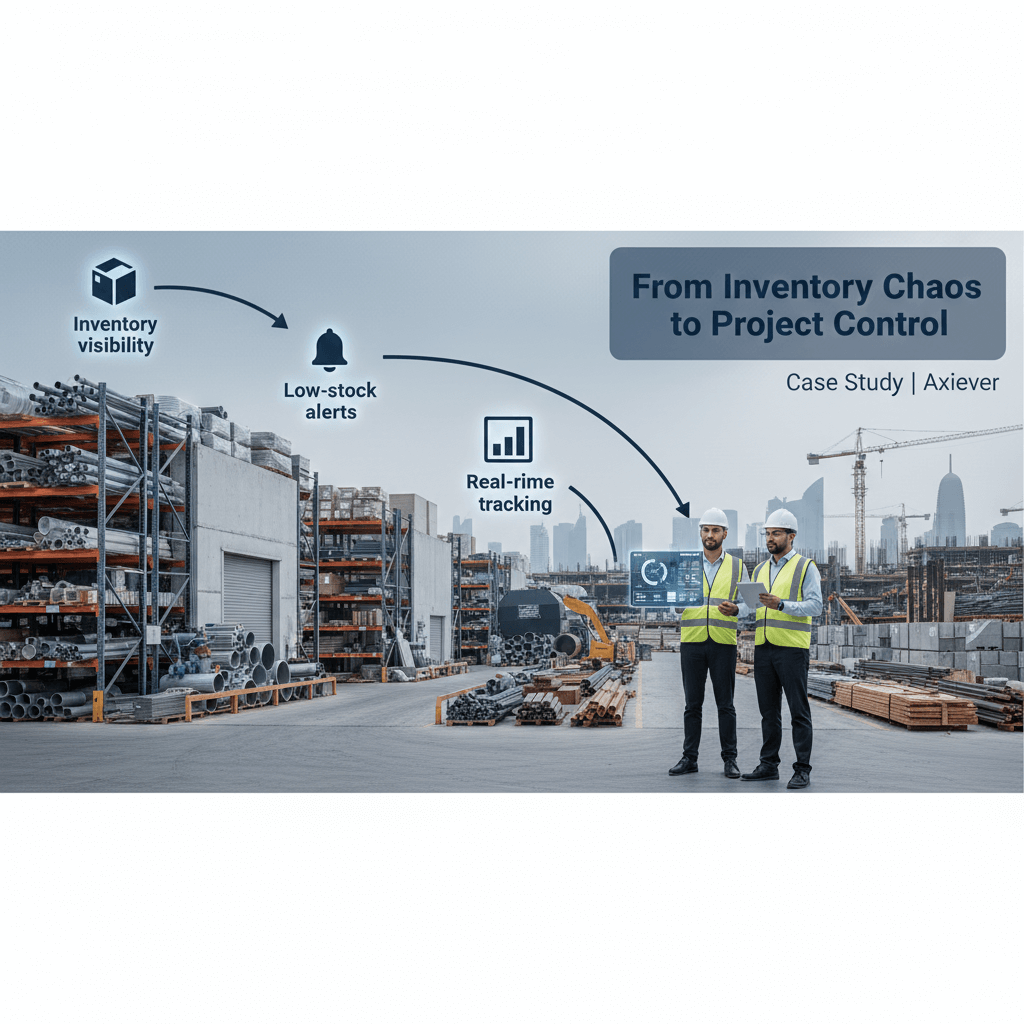

The solution: Axiever for project based inventory control

Axiever was implemented as a centralized inventory and warehouse management system across all storage locations and project sites.

Every receipt, issue, transfer and return was captured in real time, embedding control directly into daily material movement workflows.

How Axiever solved the challenges

- Standardized item master and SKU control

- Real time inventory accuracy

- Automated low stock alerts

- Overstock and dead stock visibility

- Structured GRN and receiving process

- Batch, lot and expiry tracking

- Accurate picking and site issue validation

- Damaged and scrap material segregation

- Warehouse, yard and site traceability

- Inventory value vs project usage insights

Business impact

- Consistent inventory accuracy

- Predictable material availability

- Reduced emergency purchases

- Lower material wastage

- Improved project cost control

- Better on-time project execution

Client testimonial

— Operations manager, MEP contracting company, Doha (Qatar)

Why this case matters for Qatar businesses

Qatar’s contracting environment demands tight control over materials, timelines and costs. This case demonstrates how structured inventory discipline, supported by Axiever, directly improves project execution and profitability.